1. Step: Logistics

Shock absorbers are transported via courier, train or post.

2. Step: Opening the absorber

The shock absorber sleeve is cut. Now the absorber can be opened using a special tool.

3. Step: Oil recycling

The reusable ‘oil’ material is collected and returned to the relevant industry.

4. Phase: Absorber disassembly

The shock absorber is dismantled, cleaned and surveyed. Wear parts are restored or replaced as required. We only use parts from well-known manufacturers.

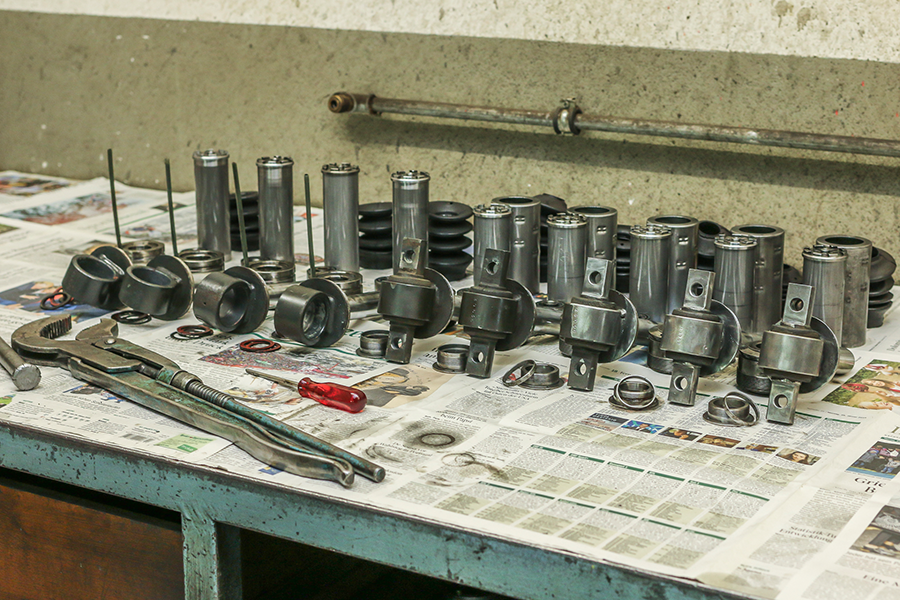

5. Step: All parts at a glance

All parts are cleaned by us. They are then reassembled step by step. Competency and precision form the basis and guarantee for functionality of the new shock absorber.

6. Step: Leakage check

Each absorber is placed under pressure for a minimum of 24 hours and checked for leakages.

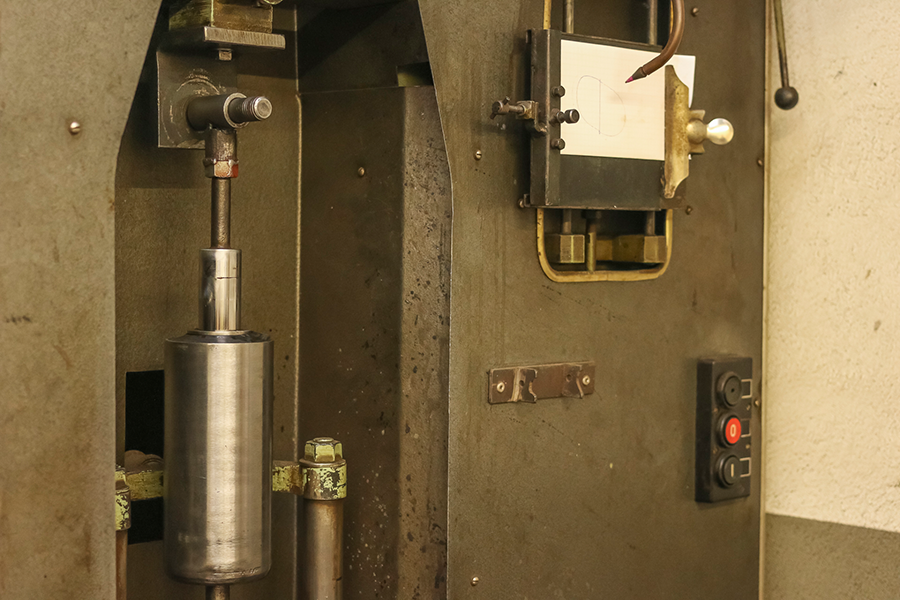

7. Step: Benchmark test

All shock absorbers have to prove their functionality under test conditions.

8. Step: Painting the absorber

Standard colours are black and red. However, we can also amend the ‘outfit’ of your absorbers to meet your requirements. We can paint your new shock absorbers in your desired colour.